Ford Explorer: Police Equipment / Diagnosis and Testing - Flasher Lighting, Siren and Speaker System

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Diagnostic Trouble Code Chart

| Module | DTC | Description | Action |

|---|---|---|---|

| BCM | B12F4:12 | Vehicle Speed Output: Circuit Short To Battery | GO to Pinpoint Test M |

| BCM | B12F4:14 | Vehicle Speed Output: Circuit Short To Ground or Open | GO to Pinpoint Test M |

| BCM | B1512:11 | Police Idle Switch: Circuit Short To Ground | GO to Pinpoint Test K |

| TRM | C0052:12 | Steering Wheel Position Sensor "Signal A": Circuit Short To Battery | GO to Pinpoint Test J |

| TRM | C0052:14 | Steering Wheel Position Sensor "Signal A": Circuit Short To Ground or Open | GO to Pinpoint Test J |

| TRM | C0053:12 | Steering Wheel Position Sensor "Signal B": Circuit Short To Battery | GO to Pinpoint Test J |

| TRM | C0053:14 | Steering Wheel Position Sensor "Signal B": Circuit Short To Ground or Open | GO to Pinpoint Test J |

| TRM | C0054:12 | Steering Wheel Position Sensor "Signal C": Circuit Short To Battery | GO to Pinpoint Test J |

| TRM | C0054:14 | Steering Wheel Position Sensor "Signal C": Circuit Short To Ground or Open | GO to Pinpoint Test J |

| TRM | C0055:12 | Steering Wheel Position Sensor "Signal D": Circuit Short To Battery | GO to Pinpoint Test J |

| TRM | C0055:14 | Steering Wheel Position Sensor "Signal D": Circuit Short To Ground or Open | GO to Pinpoint Test J |

Symptom Chart(s)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart: Flasher Lighting, Siren and Speaker System

Symptom Chart

| Condition | Possible Sources | Actions |

|---|---|---|

| A module does not respond to the diagnostic scan tool |

|

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing). |

| A spotlamp is inoperative or always on | Refer to the Pinpoint Test | GO to Pinpoint Test A |

| All flashing Light Emitting Diodes (LEDs) are inoperative | Refer to the Pinpoint Test | GO to Pinpoint Test B |

| An individual or group of flashing Light Emitting Diodes (LEDs) is inoperative or always on - grille, headlamp, exterior mirror and, if equipped, front auxiliary Flashing Light Emitting Diodes (LEDs) | Refer to the Pinpoint Test | GO to Pinpoint Test C |

| An individual or group of flashing Light Emitting Diodes (LEDs) is inoperative or always on - quarter glass, rear lamp, high mount and liftgate (underside) flashing Light Emitting Diodes (LEDs) | Refer to the Pinpoint Test | GO to Pinpoint Test D |

| An individual or group of flashing Light Emitting Diodes (LEDs) do not synchronize correctly or display an incorrect pattern - grille, exterior mirror and, if equipped, front auxiliary flashing Light Emitting Diodes (LEDs | Refer to the Pinpoint Test | GO to Pinpoint Test E |

| An individual or group of flashing Light Emitting Diodes (LEDs) do not synchronize correctly or display an incorrect pattern - rear lamp, high mount and liftgate (underside) flashing Light Emitting Diodes (LEDs) | GO to Pinpoint Test F | |

| The headlamp flashing Light Emitting Diodes (LEDs) do not synchronize correctly | GO to Pinpoint Test G | |

| The wig-wag function does not operate the high beams correctly | Refer to the Pinpoint Test | GO to Pinpoint Test H |

| The siren speaker is inoperative | Refer to the Pinpoint Test | GO to Pinpoint Test I |

| The steering wheel auxiliary controls are inoperative or do not operate correctly | Refer to the Pinpoint Test | GO to Pinpoint Test J |

| The police idle system will not activate or is always active | Refer to the Pinpoint Test | GO to Pinpoint Test K |

| The police perimeter alert system system will not activate or is always active | Refer to the Pinpoint Test | GO to Pinpoint Test L |

| The customer access speed signal input is inoperative | Refer to the Pinpoint Test | GO to Pinpoint Test M |

| The visor flashing Light Emitting Diodes (LEDs), front fascia flashing Light Emitting Diodes (LEDs) and/or the rear traffic control flashing Light Emitting Diodes (LEDs) are inoperative or do not operate correctly | Refer to the Pinpoint Test | GO to Pinpoint Test N |

Pinpoint Tests

PINPOINT TEST A : A SPOTLAMP IS INOPERATIVE OR ALWAYS ON

PINPOINT TEST A : A SPOTLAMP IS INOPERATIVE OR ALWAYS ON |

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||

| A1 DETERMINE IF THE SPOTLAMP IS ALWAYS ON | ||||||||||||||||

Is the spotlamp always illuminated?

|

||||||||||||||||

| A2 CHECK THE SPOTLAMP VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||||||||

Is the voltage greater than 11 volts?

|

PINPOINT TEST B : ALL FLASHING LIGHT EMITTING DIODES (LEDS) ARE INOPERATIVE

PINPOINT TEST B : ALL FLASHING LIGHT EMITTING DIODES (LEDS) ARE INOPERATIVE|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||

| B1 CHECK THE LIGHTING CONTROL VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| B2 CHECK THE LIGHTING CONTROL GROUND CIRCUIT | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| B3 CHECK THE LIGHTING CONTROL VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| B4 CHECK THE CONTROL HEAD | ||||||||||

Is the concern still present?

|

||||||||||

| B5 CHECK FOR CORRECT LIGHTING CONTROL OPERATION | ||||||||||

Is the concern still present?

|

||||||||||

| B6 CHECK FOR CORRECT BCMC (BODY CONTROL MODULE C) OPERATION | ||||||||||

Is the concern still present?

|

PINPOINT

TEST C : AN INDIVIDUAL OR GROUP OF FLASHING LIGHT EMITTING DIODES

(LEDS) IS INOPERATIVE OR ALWAYS ON - GRILLE, HEADLAMP, EXTERIOR MIRROR

AND, IF EQUIPPED, FRONT AUXILIARY FLASHING LIGHT EMITTING DIODES (LEDS)

PINPOINT

TEST C : AN INDIVIDUAL OR GROUP OF FLASHING LIGHT EMITTING DIODES

(LEDS) IS INOPERATIVE OR ALWAYS ON - GRILLE, HEADLAMP, EXTERIOR MIRROR

AND, IF EQUIPPED, FRONT AUXILIARY FLASHING LIGHT EMITTING DIODES (LEDS)|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C1 CHECK THE FLASHING LIGHT EMITTING DIODES (LEDS) OPERATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is only an individual flashing LED inoperative?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C2 CHECK THE FLASHING LIGHT EMITTING DIODES (LEDS) VOLTAGE FEED CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C3 CHECK THE FLASHING LIGHT EMITTING DIODES (LEDS) VOLTAGE FEED CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the grille, headlamp, exterior mirror and, if equipped, front auxiliary flashing Light Emitting Diodes (LEDs) still on?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C4 CHECK FOR VOLTAGE TO THE FLASHING LED (LIGHT EMITTING DIODE) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C5 CHECK FLASHING LED (LIGHT EMITTING DIODE) GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C6 CHECK THE CONTROL HEAD | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C7 CHECK FOR CORRECT LIGHTING CONTROL OPERATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT

TEST D : AN INDIVIDUAL OR GROUP OF FLASHING LIGHT EMITTING DIODES

(LEDS) IS INOPERATIVE OR ALWAYS ON - QUARTER GLASS, REAR LAMP, HIGH

MOUNT AND LIFTGATE (UNDERSIDE) FLASHING LIGHT EMITTING DIODES (LEDS)

PINPOINT

TEST D : AN INDIVIDUAL OR GROUP OF FLASHING LIGHT EMITTING DIODES

(LEDS) IS INOPERATIVE OR ALWAYS ON - QUARTER GLASS, REAR LAMP, HIGH

MOUNT AND LIFTGATE (UNDERSIDE) FLASHING LIGHT EMITTING DIODES (LEDS)|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D1 CHECK THE FLASHING LIGHT EMITTING DIODES (LEDS) OPERATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is only an individual flashing LED inoperative?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D2 CHECK THE QUARTER GLASS AND REAR LAMP FLASHING LIGHT EMITTING DIODES (LEDS) VOLTAGE CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D3 CHECK THE HIGH MOUNT AND THE LIFTGATE (UNDERSIDE) FLASHING LIGHT EMITTING DIODES (LEDS) VOLTAGE CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D4 CHECK THE FLASHING LIGHT EMITTING DIODES (LEDS) VOLTAGE FEED CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D5 CHECK THE FLASHING LIGHT EMITTING DIODES (LEDS) VOLTAGE FEED CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the quarter glass, rear lamp, high mount and liftgate (underside) flashing Light Emitting Diodes (LEDs) still on?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D6 CHECK THE FLASHING LED (LIGHT EMITTING DIODE) VOLTAGE CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D7 CHECK THE FLASHING LED (LIGHT EMITTING DIODE) GROUND CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D8 CHECK THE CONTROL HEAD | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| D9 CHECK FOR CORRECT LIGHTING CONTROL OPERATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT

TEST E : AN INDIVIDUAL OR GROUP OF FLASHING LIGHT EMITTING DIODES

(LEDS) DO NOT SYNCHRONIZE CORRECTLY OR DISPLAY AN INCORRECT PATTERN -

GRILLE, EXTERIOR MIRROR AND, IF EQUIPPED, FRONT AUXILIARY FLASHING LIGHT

EMITTING DIODES (LEDS)

PINPOINT

TEST E : AN INDIVIDUAL OR GROUP OF FLASHING LIGHT EMITTING DIODES

(LEDS) DO NOT SYNCHRONIZE CORRECTLY OR DISPLAY AN INCORRECT PATTERN -

GRILLE, EXTERIOR MIRROR AND, IF EQUIPPED, FRONT AUXILIARY FLASHING LIGHT

EMITTING DIODES (LEDS)|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

|

||||||||||||||||||||||||||||||||||||||||

| E1 CHECK THE FLASHING LIGHT EMITTING DIODES (LEDS) OPERATION | ||||||||||||||||||||||||||||||||||||||||

Does the suspect flashing LED or Light Emitting Diodes (LEDs) display the same pattern as the others in the group?

|

||||||||||||||||||||||||||||||||||||||||

| E2 CHECK THE INCORRECTLY FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| E3 CHECK THE FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

||||||||||||||||||||||||||||||||||||||||

| E4 CHECK THE FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR A SHORT TO GROUND | ||||||||||||||||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| E5 CHECK THE INCORRECTLY FLASHING LED (LIGHT EMITTING DIODE) PATTERN CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| E6 CHECK THE FLASHING LED (LIGHT EMITTING DIODE) PATTERN CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

PINPOINT

TEST F : AN INDIVIDUAL OR GROUP OF FLASHING LIGHT EMITTING DIODES

(LEDS) DO NOT SYNCHRONIZE CORRECTLY OR DISPLAY AN INCORRECT PATTERN -

REAR LAMP, HIGH MOUNT AND LIFTGATE (UNDERSIDE) FLASHING LIGHT EMITTING

DIODES (LEDS)

PINPOINT

TEST F : AN INDIVIDUAL OR GROUP OF FLASHING LIGHT EMITTING DIODES

(LEDS) DO NOT SYNCHRONIZE CORRECTLY OR DISPLAY AN INCORRECT PATTERN -

REAR LAMP, HIGH MOUNT AND LIFTGATE (UNDERSIDE) FLASHING LIGHT EMITTING

DIODES (LEDS)|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

|

||||||||||||||||||||||||||||||||||||||||

| F1 CHECK THE FLASHING LIGHT EMITTING DIODES (LEDS) OPERATION | ||||||||||||||||||||||||||||||||||||||||

Does the suspect flashing LED or Light Emitting Diodes (LEDs) display the same pattern as the others in the group?

|

||||||||||||||||||||||||||||||||||||||||

| F2 CHECK THE INCORRECTLY FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| F3 CHECK THE FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

||||||||||||||||||||||||||||||||||||||||

| F4 CHECK THE FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR A SHORT TO GROUND | ||||||||||||||||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| F5 CHECK THE INCORRECTLY FLASHING LED (LIGHT EMITTING DIODE) PATTERN CIRCUIT FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||

| F6 CHECK THE FLASHING LED (LIGHT EMITTING DIODE) PATTERN CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

PINPOINT TEST G : THE HEADLAMP FLASHING LIGHT EMITTING DIODES (LEDS) DO NOT SYNCHRONIZE CORRECTLY

PINPOINT TEST G : THE HEADLAMP FLASHING LIGHT EMITTING DIODES (LEDS) DO NOT SYNCHRONIZE CORRECTLY|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

|

||||||||||

| G1 CHECK THE HEADLAMP FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| G2 CHECK THE HEADLAMP FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| G3 CHECK THE HEADLAMP FLASHING LED (LIGHT EMITTING DIODE) SYNCHRONIZE CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| G4 CHECK THE HEADLAMP FLASHING LED (LIGHT EMITTING DIODE) | ||||||||||

Is the concern still present?

|

PINPOINT TEST H : THE WIG-WAG FUNCTION DOES NOT OPERATE THE HIGH BEAMS CORRECTLY

PINPOINT TEST H : THE WIG-WAG FUNCTION DOES NOT OPERATE THE HIGH BEAMS CORRECTLY|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

|

||||||||||

| H1 VERIFY THE HIGH BEAM HEADLAMP OPERATION | ||||||||||

Do the high beam headlamps illuminate correctly?

|

||||||||||

| H2 CHECK THE LIGHTING CONTROL WIG-WAG FUNCTION GROUND CIRCUIT | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| H3 CHECK THE WIG-WAG GROUND FEED CIRCUIT TO THE BCM (BODY CONTROL MODULE) | ||||||||||

Does the high beam wig-wag function operate?

|

||||||||||

| H4 CHECK THE WIG-WAG GROUND FEED CIRCUIT TO THE BCM (BODY CONTROL MODULE) FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| H5 CHECK THE CORRECT SIREN/LIGHTING CONTROL MODULE | ||||||||||

Are the high beam wig-wags on?

|

||||||||||

| H6 CHECK THE WIG-WAG GROUND FEED CIRCUIT TO THE BCM (BODY CONTROL MODULE) FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| H7 CHECK THE CONTROL HEAD | ||||||||||

Is the concern still present?

|

||||||||||

| H8 CHECK FOR CORRECT LIGHTING CONTROL OPERATION | ||||||||||

Is the concern still present?

|

||||||||||

| H9 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

PINPOINT TEST I : THE SIREN SPEAKER IS INOPERATIVE

PINPOINT TEST I : THE SIREN SPEAKER IS INOPERATIVE |

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

|||||||||||||

| I1 CHECK THE SIREN SPEAKER FUNCTIONALITY | |||||||||||||

Are both the siren and loudspeaker functions inoperative?

|

|||||||||||||

| I2 CHECK THE MICROPHONE | |||||||||||||

Does the loudspeaker system operate?

|

|||||||||||||

| I3 CHECK THE MODULE OPERATION | |||||||||||||

Does the lighting and siren control module make any audible siren sound?

|

|||||||||||||

| I4 CHECK SIREN SPEAKER INPUT | |||||||||||||

Is AC voltage present?

|

|||||||||||||

| I5 CHECK SIREN SPEAKER INPUT | |||||||||||||

Are the resistances less than 3 ohms?

|

|||||||||||||

| I6 CHECK FOR CORRECT LIGHTING CONTROL OPERATION | |||||||||||||

Is the concern still present?

|

PINPOINT TEST J : THE STEERING WHEEL AUXILIARY CONTROLS ARE INOPERATIVE OR DO NOT OPERATE CORRECTLY

PINPOINT TEST J : THE STEERING WHEEL AUXILIARY CONTROLS ARE INOPERATIVE OR DO NOT OPERATE CORRECTLY|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||||||||||||||||||

| J1 CHECK FOR TRM (TRAILER MODULE) DIAGNOSTIC TROUBLE CODE (DTCS) | ||||||||||||||||||||||||||||

Are TRM Diagnostic Trouble Code (DTCs) present?

|

||||||||||||||||||||||||||||

| J2 CHECK FOR VOLTAGE TO THE STEERING WHEEL SWITCH | ||||||||||||||||||||||||||||

Are the voltages approximately 5 volts?

|

||||||||||||||||||||||||||||

| J3 CHECK THE STEERING WHEEL HARNESS | ||||||||||||||||||||||||||||

Are the voltages approximately 5 volts?

|

||||||||||||||||||||||||||||

| J4 CHECK FOR DTC (DIAGNOSTIC TROUBLE CODE) B137F:11 AND B1380:11 | ||||||||||||||||||||||||||||

Is DTC B137F:11 or B1380:11 present?

|

||||||||||||||||||||||||||||

| J5 CHECK THE CLOCKSPRING FOR A SHORT TO GROUND | ||||||||||||||||||||||||||||

Is DTC B137F:11 or B1380:11 still present?

|

||||||||||||||||||||||||||||

| J6 CHECK THE CLOCKSPRING FOR AN OPEN | ||||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||||||||||||

| J7 CHECK FOR CORRECT SCCM (STEERING COLUMN CONTROL MODULE) OPERATION | ||||||||||||||||||||||||||||

Is the concern still present?

|

||||||||||||||||||||||||||||

| J8 CHECK THE TRM (TRAILER MODULE) FOR SHORT TO VOLTAGE | ||||||||||||||||||||||||||||

Does the DTC return?

|

||||||||||||||||||||||||||||

| J9 CHECK THE STEERING WHEEL CONTROL TRM (TRAILER MODULE) OUTPUT CIRCUITS FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||

| J10 CHECK THE CUSTOMER-INSTALLED EQUIPMENT | ||||||||||||||||||||||||||||

Does the DTC return?

|

||||||||||||||||||||||||||||

| J11 CHECK THE STEERING WHEEL CONTROL TRM (TRAILER MODULE) OUTPUT CIRCUITS FOR A SHORT TO GROUND | ||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||

| J12 CHECK THE STEERING WHEEL CONTROL TRM (TRAILER MODULE) OUTPUT CIRCUITS FOR AN OPEN | ||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

||||||||||||||||||||||||||||

| J13 CHECK FOR CORRECT TRM (TRAILER MODULE) OPERATION | ||||||||||||||||||||||||||||

Is the concern still present?

|

PINPOINT TEST K : THE POLICE IDLE SYSTEM WILL NOT ACTIVATE OR IS ALWAYS ACTIVE

PINPOINT TEST K : THE POLICE IDLE SYSTEM WILL NOT ACTIVATE OR IS ALWAYS ACTIVE|

Refer to Wiring Diagrams Cell 109 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||

| K1 CHECK FOR BCM (BODY CONTROL MODULE) DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||

Is DTC B1512:11 present?

|

||||||||||

| K2 ISOLATE THE POLICE IDLE SWITCH | ||||||||||

Is DTC B1512:11 retrieved again?

|

||||||||||

| K3 CHECK THE POLICE IDLE SWITCH INPUT CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| K4 CHECK FOR A VOLTAGE SIGNAL TO THE POLICE IDLE SWITCH | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| K5 CHECK THE POLICE IDLE SWITCH GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| K6 CHECK THE POLICE IDLE SWITCH INPUT CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| K7 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

PINPOINT TEST L : THE POLICE PERIMETER ALERT SYSTEM WILL NOT ACTIVATE OR IS ALWAYS ACTIVE

PINPOINT TEST L : THE POLICE PERIMETER ALERT SYSTEM WILL NOT ACTIVATE OR IS ALWAYS ACTIVE|

Refer to Wiring Diagrams Cell 109 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

|

||||||||||

| L1 CHECK POLICE PERIMETER ALERT SYSTEM CURRENT OPERATION | ||||||||||

Does the instrument cluster always display the police perimeter alert system?

|

||||||||||

| L2 ISOLATE THE BOUNDARY ALERT SWITCH | ||||||||||

Does the instrument cluster display the police perimeter alert system?

|

||||||||||

| L3 CHECK THE BOUNDARY ALERT SWITCH INPUT CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| L4 CHECK FOR A VOLTAGE SIGNAL TO THE BOUNDARY ALERT SWITCH | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| L5 CHECK THE BOUNDARY ALERT SWITCH GROUND CIRCUIT FOR AN OPEN | ||||||||||

Is the voltage greater than 11 volts?

|

||||||||||

| L6 CHECK THE BOUNDARY ALERT SWITCH INPUT CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| L7 CHECK FOR CORRECT IPC (INSTRUMENT PANEL CLUSTER) OPERATION | ||||||||||

Is the concern still present?

|

PINPOINT TEST M : THE CUSTOMER ACCESS SPEED SIGNAL INPUT IS INOPERATIVE

PINPOINT TEST M : THE CUSTOMER ACCESS SPEED SIGNAL INPUT IS INOPERATIVE|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||

| M1 CHECK THE VEHICLE SPEEDOMETER OPERATION | ||||||||||

Does the vehicle speedometer operate?

|

||||||||||

| M2 CHECK FOR A VOLTAGE SIGNAL TO THE CUSTOMER ACCESS CONNECTOR | ||||||||||

Does the voltage increase with the vehicle wheel speed?

|

||||||||||

| M3 CHECK THE VEHICLE SPEED CIRCUIT FOR A SHORT TO VOLTAGE | ||||||||||

Is any voltage present?

|

||||||||||

| M4 CHECK THE VEHICLE SPEED CIRCUIT FOR A SHORT TO GROUND | ||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||

| M5 CHECK THE VEHICLE SPEED CIRCUIT FOR AN OPEN | ||||||||||

Is the resistance less than 3 ohms?

|

||||||||||

| M6 CHECK FOR CORRECT BCM (BODY CONTROL MODULE) OPERATION | ||||||||||

Is the concern still present?

|

PINPOINT

TEST N : THE VISOR FLASHING LIGHT EMITTING DIODES (LEDS), FRONT FASCIA

FLASHING LIGHT EMITTING DIODES (LEDS) AND/OR THE REAR TRAFFIC CONTROL

FLASHING LIGHT EMITTING DIODES (LEDS) ARE INOPERATIVE OR DO NOT OPERATE

CORRECTLY

PINPOINT

TEST N : THE VISOR FLASHING LIGHT EMITTING DIODES (LEDS), FRONT FASCIA

FLASHING LIGHT EMITTING DIODES (LEDS) AND/OR THE REAR TRAFFIC CONTROL

FLASHING LIGHT EMITTING DIODES (LEDS) ARE INOPERATIVE OR DO NOT OPERATE

CORRECTLY|

Refer to Wiring Diagrams Cell 96 for schematic and connector information. Normal Operation and Fault Conditions

REFER to: Flasher Lighting, Siren and Speaker System - System Operation and Component Description (100-05 Police Equipment, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

|||||||||||||||||||||||||||||||||||||||||||

| N1 CHECK FOR INOPERATIVE FLASHING LIGHT EMITTING DIODES (LEDS) | |||||||||||||||||||||||||||||||||||||||||||

Are all the visor flashing Light Emitting Diodes (LEDs), front fascia Flashing Light Emitting Diodes (LEDs) and the rear traffic control flashing Light Emitting Diodes (LEDs) inoperative?

|

|||||||||||||||||||||||||||||||||||||||||||

| N2 CHECK FOR FLASHING LIGHT EMITTING DIODES (LEDS) ALWAYS ON | |||||||||||||||||||||||||||||||||||||||||||

Are the visor flashing Light Emitting Diodes (LEDs), front fascia Flashing Light Emitting Diodes (LEDs) and the rear traffic control flashing Light Emitting Diodes (LEDs) always on?

|

|||||||||||||||||||||||||||||||||||||||||||

| N3 CHECK TRAFFIC CONTROL FLASHING LED (LIGHT EMITTING DIODE) CONTROL MODULE CONTROL VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||||||||||||||||||||||||

| N4 CHECK TRAFFIC ADVISOR CONTROL VOLTAGE GROUND CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||||||||||||||||||||||||

| N5 CHECK THE DATA CIRCUIT FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||||||||||||||||||

| N6 CHECK THE DATA CIRCUIT FOR A SHORT TO GROUND | |||||||||||||||||||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||

| N7 CHECK THE DATA CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||

| N8 CHECK THE INOPERATIVE FLASHING LED (LIGHT EMITTING DIODE) VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||||||||||||||||||||||||

| N9 CHECK THE INOPERATIVE FLASHING LED (LIGHT EMITTING DIODE) GROUND CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||||||||||||||||||||||||

| N10 CHECK THE CHECK THE INOPERATIVE FLASHING LED (LIGHT EMITTING DIODE) DATA CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||

| N11 CHECK THE INOPERATIVE FLASHING LIGHT EMITTING DIODES (LEDS) VOLTAGE SUPPLY CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||||||||||||||||||||||||

| N12 CHECK THE INOPERATIVE FLASHING LIGHT EMITTING DIODES (LEDS) GROUND CIRCUIT FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the voltage greater than 11 volts?

|

|||||||||||||||||||||||||||||||||||||||||||

| N13 CHECK THE TRAFFIC ADVISOR INPUT CIRCUITS FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||||||||||||||||||

Is any voltage present?

|

|||||||||||||||||||||||||||||||||||||||||||

| N14 CHECK THE TRAFFIC ADVISOR INPUT CIRCUITS FOR A SHORT TO GROUND | |||||||||||||||||||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||

| N15 CHECK THE TRAFFIC ADVISOR INPUT CIRCUITS FOR AN OPEN | |||||||||||||||||||||||||||||||||||||||||||

Is the resistance less than 3 ohms?

|

|||||||||||||||||||||||||||||||||||||||||||

| N16 CHECK THE TRAFFIC CONTROL FLASHING LED (LIGHT EMITTING DIODE) CONTROL MODULE | |||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

|||||||||||||||||||||||||||||||||||||||||||

| N17 CHECK THE CONTROL HEAD | |||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

|||||||||||||||||||||||||||||||||||||||||||

| N18 CHECK FOR CORRECT LIGHTING CONTROL OPERATION | |||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

Description and Operation - Flasher Lighting, Siren and Speaker System - System Operation and Component Description

Description and Operation - Flasher Lighting, Siren and Speaker System - System Operation and Component Description

System Operation

Description and Operation

Spotlamps

The LH and RH

spotlamps are mounted on the A-pillers and are equipped with Light

Emitting Diodes (LEDs)...

General Procedures - Group Flash Pattern Programming

General Procedures - Group Flash Pattern Programming

Activation

WARNING:

Police Package warning lights are a high-intensity

Light-Emitting Diode (LED) type. Do not stare directly at these lights,

as doing so may cause temporary blindn..

Other information:

Ford Explorer 2020-2026 Owners Manual: Illuminated Entry & Illuminated Exit

Illuminated Entry The interior lamps and some exterior lamps illuminate when you unlock the doors with the remote control. The lamps turn off if: The ignition is on. You press the remote control lock button. 25 seconds have elapsed. The lamps do not turn off if: You switch them on with the lighting control...

Ford Explorer 2020-2026 Service Manual: General Procedures - Air Conditioning (A/C) System Recovery, Evacuation and Charging - Vehicles With: R1234YF Refrigerant

Special Tool(s) / General Equipment Air Conditioning Service Unit Refrigerant Identification Equipment Recovery NOTICE: Use an A/C refrigerant analyzer before recovering any of the vehicle's A/C refrigerant. Failure to do so puts the shop's bulk refrigerant at risk of contamination...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Description and Operation - Jacking and Lifting - Overview

- Using Tether Straps

- Removal and Installation - Front Halfshaft Speed Sensor

- New on site

- Most important about car

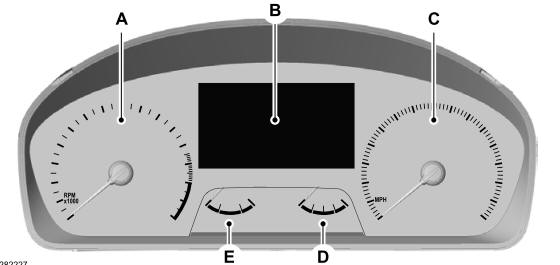

Gauges

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.

PINPOINT TEST A : A SPOTLAMP IS INOPERATIVE OR ALWAYS ON

PINPOINT TEST A : A SPOTLAMP IS INOPERATIVE OR ALWAYS ON .jpg)

.jpg)

.jpg)

.jpg)

.jpg) Upper Clockspring C218B, pin 10 (component side)

Upper Clockspring C218B, pin 10 (component side)

.jpg) Lower Clockspring C218F, pin 4 (component side)

Lower Clockspring C218F, pin 4 (component side)

.jpg)