Ford Explorer: Climate Control System - General Information / General Procedures - Air Conditioning (A/C) System Recovery, Evacuation and Charging - Vehicles With: R1234YF Refrigerant

Special Tool(s) / General Equipment

| Air Conditioning Service Unit | |

| Refrigerant Identification Equipment |

Recovery

NOTICE: Use an A/C refrigerant analyzer before recovering any of the vehicle's A/C refrigerant. Failure to do so puts the shop's bulk refrigerant at risk of contamination. If the vehicle's A/C refrigerant is contaminated, refer the customer to the service facility that carried out the last A/C service. If the customer wishes to pay the additional cost, use the A/C recovery equipment that is designated for recovering contaminated A/C refrigerant. Dispose of all contaminated A/C refrigerant as hazardous waste in accordance with all federal, state and local regulations. For all equipment, follow the manufacturer's instructions.

-

NOTE: Use only Ford Approved R1234yf refrigerant management equipment.

Verify the refrigerant purity prior to recovery. Refer to Refrigerant Identification Testing procedure in Group 412.

-

198-RI2012yfp A/C Refrigerant Analyzer for use with R1234yf vehicles

Use the General Equipment: Refrigerant Identification Equipment

-

198-RI2012yfp A/C Refrigerant Analyzer for use with R1234yf vehicles

-

Connect the tool to the low-side and high-side service

gauge port valves following the manufacturer's instructions.

-

199-FFX1234 Flo Dynamics R1234yf A/C Refrigerant Management Center

Use the General Equipment: Air Conditioning Service Unit

-

023-AC1234-6LD Robinair R1234yf A/C Refrigerant Management Center

Use the General Equipment: Air Conditioning Service Unit

-

218-FFX1234 CPS R1234yf A/C Refrigerant Management Center.

-

199-FFX1234 Flo Dynamics R1234yf A/C Refrigerant Management Center

-

NOTE: Never attempt to recover from only the low side service gauge port valve (solenoid valves in the system will not allow for full recovery). Open solenoid valves.

Recover the refrigerant from the system following the manufacturer's instructions. Note the amount of oil removed during the refrigerant recovery (if any). Add that same amount back into the system once repairs are complete. Refer to Refrigerant Oil Adding procedure in Group 412.

-

Allow the system to set for about 2 minutes and observe

the system vacuum reading. If the vacuum is not lost, disconnect the

recovery equipment.

-

If the system loses vacuum, repeat Steps 3 through 5 until the vacuum level remains stable for 2 minutes.

-

Carry out the required repairs.

Evacuation

-

NOTICE: Use an A/C refrigerant analyzer before recovering any of the vehicle's refrigerant. Failure to do so puts the shop's bulk refrigerant at risk of contamination. If the vehicle's A/C refrigerant is contaminated, refer the customer to the service facility that carried out the last A/C service. If the customer wishes to pay the additional cost, use the A/C recovery equipment that is designated for recovering contaminated A/C refrigerant. Dispose of all contaminated A/C refrigerant as hazardous waste in accordance with all federal, state and local regulations. For all equipment, follow the manufacturer's instructions.

-

198-RI2012yfp A/C Refrigerant Analyzer for use with R1234yf vehicles

Use the General Equipment: Refrigerant Identification Equipment

-

198-RI2012yfp A/C Refrigerant Analyzer for use with R1234yf vehicles

-

Connect the tool to the low-side and high-side service

gauge port valves following the manufacturer's instructions.

-

199-FFX1234 Flo Dynamics R1234yf A/C Refrigerant Management Center

Use the General Equipment: Air Conditioning Service Unit

-

023-AC1234-6LD Robinair R1234yf A/C Refrigerant Management Center

Use the General Equipment: Air Conditioning Service Unit

-

218-FFX1234 CPS R1234yf A/C Refrigerant Management Center.

-

199-FFX1234 Flo Dynamics R1234yf A/C Refrigerant Management Center

-

NOTE: Never attempt to recover from only the low side service gauge port valve (solenoid valves in the system will not allow for full recovery). Open solenoid valves.

Evacuate the system until the low-pressure gauge reads at least 99.4 kPa (29.5 in-Hg) of vacuum and as close to 101.1 kPa (30 in-Hg) as possible. Continue to operate the vacuum pump for a minimum of 45 minutes.

-

Turn off the vacuum pump. Observe the low-pressure gauge for 10 minutes to make sure the system vacuum is held.

Charging

-

NOTICE: Use an A/C refrigerant analyzer before recovering any of the vehicle's refrigerant. Failure to do so puts the shop's bulk refrigerant at risk of contamination. If the vehicle's A/C refrigerant is contaminated, refer the customer to the service facility that carried out the last A/C service. If the customer wishes to pay the additional cost, use the A/C recovery equipment that is designated for recovering contaminated A/C refrigerant. Dispose of all contaminated A/C refrigerant as hazardous waste in accordance with all federal, state and local regulations. For all equipment, follow the manufacturer's instructions.

-

198-RI2012yfp A/C Refrigerant Analyzer for use with R1234yf vehicles

Use the General Equipment: Refrigerant Identification Equipment

-

198-RI2012yfp A/C Refrigerant Analyzer for use with R1234yf vehicles

-

Lubricate the refrigerant system with the correct amount

of clean PAG oil. Refer to the appropriate Refrigerant Oil Adding

procedure in Group 412.

-

Connect the tool to the low-side and high-side service

gauge port valves following the manufacturer's instructions.

-

199-FFX1234 Flo Dynamics R1234yf A/C Refrigerant Management Center

Use the General Equipment: Air Conditioning Service Unit

-

023-AC1234-6LD Robinair R1234yf A/C Refrigerant Management Center

Use the General Equipment: Air Conditioning Service Unit

-

218-FFX1234 CPS R1234yf A/C Refrigerant Management Center.

-

199-FFX1234 Flo Dynamics R1234yf A/C Refrigerant Management Center

-

Set the refrigerant charge amount and charge the refrigerant system following the manufacturer's instructions.

General Procedures - Air Conditioning (A/C) System Leak Test Using Forming Gas - Vehicles With: R134A Refrigerant/R1234YF Refrigerant

General Procedures - Air Conditioning (A/C) System Leak Test Using Forming Gas - Vehicles With: R134A Refrigerant/R1234YF Refrigerant

Special Tool(s) /

General Equipment

Forming Gas Pressure Gauge and Leak Detector

Materials

Name

Specification

Forming Gas

-

Leak detection

All vehicles

NOTE:..

General Procedures - Air Conditioning (A/C) System Recovery, Evacuation and Charging - Hybrid Electric Vehicle (HEV), Vehicles With: R1234YF Refrigerant

General Procedures - Air Conditioning (A/C) System Recovery, Evacuation and Charging - Hybrid Electric Vehicle (HEV), Vehicles With: R1234YF Refrigerant

Special Tool(s) /

General Equipment

Air Conditioning Service Unit

Refrigerant Identification Equipment

Check

NOTE:

For all equipment, follow the manufacturer's instructions...

Other information:

Ford Explorer 2020-2024 Service Manual: Removal and Installation - Driver Side Footwell Air Discharge Temperature Sensor

Removal Remove the driver side knee airbag. Refer to: Driver Knee Airbag (501-20B Supplemental Restraint System, Removal and Installation). Disconnect the electrical connector and remove the driver side footwell air discharge temperature sensor...

Ford Explorer 2020-2024 Owners Manual: Optional Settings

You can configure certain vehicle feature settings when you first create a MyKey. You can also change the settings afterward with an admin key. Note: Not every feature applies to every vehicle in every market. When they are available for your vehicle, then they appear in your information display, providing choices to switch them on or off, or to select a more specific setting...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Traction Control

- Removal and Installation - Liftgate Trim Panel

- General Procedures - Transmission Fluid Drain and Refill

- New on site

- Most important about car

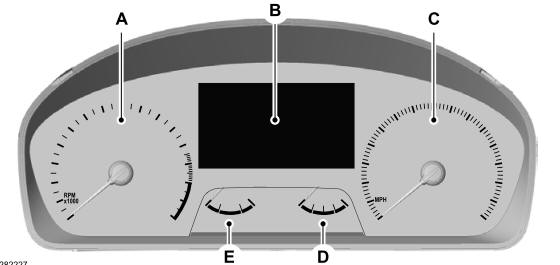

Gauges

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.