Ford Explorer: Climate Control System - General Information / General Procedures - Refrigerant System Tests - 2.3L EcoBoost (201kW/273PS)

Inspection

-

NOTE: Procedure 1 — Ambient Temperature below 21 °C (70 °F).

NOTE: Proper A/C system diagnosis on a vehicle’s compressor is dependent on correct refrigerant system charge and tested in ambient temperatures above 21°C (70°F). Perform the following steps to achieve normal operating pressures.

Drive the vehicle or run the engine until it reaches normal operating temperature.

-

Set the A/C system

temperature to the highest possible temperature setting with the dual

function disabled (if equipped). Manually set the blower on HI. If the

vehicle has a fresh air/recirc button, set it to recirculation. If the

vehicle has an A/C switch or compressor on switch, set it to A/C OFF.

-

Close all the vehicle windows and doors.

-

Allow the vehicle to idle for 5 minutes.

-

Confirm the cabin temperature is above 24 °C (75 °F). Set the A/C switch or compressor on switch to MAX A/C ON.

-

Allow the vehicle to idle for 5 minutes.

-

Turn engine off and proceed to procedure 2 — ambient temperature between 21 °C (70 °F) and 38 °C (100 °F).

Inspection

NOTE: Procedure 2— Ambient Temperature between 21°C (70°F) and 38°C (100°F)

-

Run the engine until it reaches normal operating temperature.

-

Connect the air conditioning service unit to the refrigerant system.

-

Set temperature to the lowest possible temperature

setting with the dual function disabled (if equipped). Manually set

blower on HI. If the vehicle has a fresh air/recirc button, set it to

FRESH. If the vehicle has an A/C switch or compressor on switch, set it to A/C ON.

-

Open all vehicle windows and leave the hood open for the test. Open the rear doors.

-

Confirm the compressor is operating and the engine

cooling fan(s) are operating or engaged. Allow the vehicle to idle until

the suction (low-side) and discharge (high-side) pressures are stable

or fluctuate in a range that repeats.

-

Record the ambient (shop) temperature.

-

Record the discharge pressure. If the pressure is fluctuating, record the average value.

-

Determine if the discharge pressure falls within the normal operating limits using the Normal Refrigerant Discharge Pressures 21 - 38° C (70 - 100° F) Ambient (30 - 60% Relative Humidity) chart below.

.jpg) |

-

Record the suction pressure. If the pressure is fluctuating, record the average value.

-

Determine if the suction pressure falls within the normal operating limits using the Normal Refrigerant Suction Pressures 21 - 38° C (70 - 100° F) Ambient (30 - 60% Relative Humidity) chart below.

.jpg) |

-

NOTE: Use the following table to guide diagnosis of the refrigerant system if operating pressures are outside normal limits.

Refer to the chart below.High (Discharge) Pressure Low (Suction) Pressure Component — Causes High Normal to High - Condenser — inadequate airflow.

- Engine — overheating.

Normal to High Normal - Refrigerant overcharge — air in refrigerant.

Normal to Low High - A/C Compressor — low performance.

Normal to Low Normal to High - A/C suction line — partially restricted or plugged. a

Normal to Low Low - Low refrigerant charge — leak in system.

- A/C suction line — partially restricted or plugged. b

Erratic Operation or Compressor Not Running - Ambient Air Temperature (AAT) sensor — poor connection.

- A/C pressure transducer — poor connection.

- Evaporator temperature sensor — poor connection.

- Low refrigerant charge — leak in system.

Additional Possible Components or Causes Associated With Inadequate Compressor Operation - Compressor drive belt — loose

- Compressor clutch — slipping

- Clutch coil open — shorted, or loose mounting

- Control assembly switch — dirty contacts or sticking open

- Clutch wiring circuit — high resistance, open or blown fuse

- Compressor operation interrupted by engine computer

Additional Possible Components or Causes Associated With a Damaged Compressor - Incorrect clutch air-gap

- Suction accumulator — refrigerant oil bleed hose plugged

- Refrigerant leaks

a Low pressure reading will be normal to high if restriction is downstream of service access valve.

b Low pressure reading will be low if restriction is upstream of service access valve.

Inspection

NOTE: Procedure 3— Ambient Temperature between 21 °C (70 °F) and 38 °C (100 °F)

-

Run the engine until it reaches normal operating temperature.

-

Connect the air conditioning service unit to the refrigerant system.

-

Set temperature to the lowest possible temperature

setting with the dual function disabled (if equipped). Manually set

blower on HI. If the vehicle has a fresh air/recirc button, set it to

FRESH. If the vehicle has an A/C switch or compressor on switch, set it to A/C ON.

-

Open all vehicle windows and leave the hood open for the

test. Open the rear hatch and/or rear doors (if equipped).

-

Confirm the compressor is operating and the engine

cooling fan(s) are operating or engaged. Allow the vehicle to idle until

the suction (low-side) and discharge (high-side) pressures are stable

or fluctuate in a range that repeats.

-

Record the ambient (shop) temperature.

-

Record the discharge pressure. If the pressure is fluctuating, record the average value.

-

Determine if the discharge pressure falls within the normal operating limits using the Normal Refrigerant Discharge Pressures 38 - 49° C (100 - 120° F) Ambient (15 - 40% Relative Humidity) chart below.

.jpg) |

-

Record the suction pressure. If the pressure is fluctuating, record the average value.

-

Determine if the suction pressure falls within the normal operating limits using the Normal Refrigerant Suction Pressures 38 - 49° C (100 - 120° F) Ambient (15 - 40% Relative Humidity) chart below.

.jpg) |

-

NOTE: Use the following table to guide diagnosis of the refrigerant system if operating pressures are outside normal limits.

NOTE: Proper A/C system diagnosis on vehicles with Variable compressors is dependent on correct refrigerant system charge and tested in ambient temperatures above 21°C (70°F). Never replace a Variable compressor without first recovering and recharging the A/C system to vehicle specification and retesting in ambient temperatures above 21°C (70°F).

Refer to the chart below.High (Discharge) Pressure Low (Suction) Pressure Component — Causes High Normal to High - Condenser — inadequate airflow.

- Engine — overheating.

Normal to High Normal - Refrigerant overcharge — air in refrigerant.

Normal to Low High - A/C Compressor — low performance.

Normal to Low Normal to High - A/C suction line — partially restricted or plugged. a

Normal to Low Low - Low refrigerant charge — leak in system.

- A/C suction line — partially restricted or plugged. b

Erratic Operation or Compressor Not Running - Ambient Air Temperature (AAT) sensor — poor connection.

- A/C pressure transducer — poor connection.

- Evaporator temperature sensor — poor connection.

- Low refrigerant charge — leak in system.

Additional Possible Components or Causes Associated With Inadequate Compressor Operation - Compressor drive belt — loose

- Compressor clutch — slipping

- Clutch coil open — shorted, or loose mounting

- Control assembly switch — dirty contacts or sticking open

- Clutch wiring circuit — high resistance, open or blown fuse

- Compressor operation interrupted by engine computer

Additional Possible Components or Causes Associated With a Damaged Compressor - Incorrect clutch air-gap

- Suction accumulator — refrigerant oil bleed hose plugged

- Refrigerant leaks

a Low pressure reading will be normal to high if restriction is downstream of service access valve.

b Low pressure reading will be low if restriction is upstream of service access valve.

General Procedures - Refrigerant Oil Adding - Vehicles With: R1234YF Refrigerant

General Procedures - Refrigerant Oil Adding - Vehicles With: R1234YF Refrigerant

Special Tool(s) /

General Equipment

Air Conditioning Service Unit

Refrigerant Oil Injector Set

Filling

Refer to the Refrigerant Oil Adding (when new components

are installed) c..

Removal and Installation - Air Conditioning (A/C) Compressor - 2.3L EcoBoost (201kW/273PS)

Removal and Installation - Air Conditioning (A/C) Compressor - 2.3L EcoBoost (201kW/273PS)

Materials

Name

Specification

Motorcraft® Silicone Brake Caliper Grease and Dielectric CompoundXG-3-A

ESE-M1C171-A

Removal

NOTICE:

If installing a new A/C compressor due ..

Other information:

Ford Explorer 2020-2025 Service Manual: Removal and Installation - Third Row Seat Cushion Cover

Removal Remove the third row seat cushion. Refer to: Third Row Seat Cushion (501-10C Third Row Seats, Removal and Installation). Release the retainers from the seat cushion frame. Remove the third row seat cushion cover and foam...

Ford Explorer 2020-2025 Service Manual: Removal and Installation - Axle Housing Bushing

Special Tool(s) / General Equipment 205-1066Installer, Bushing Flat Headed Screw Driver Removal NOTE: Only worn or damaged bushings need to be replaced. Remove the rear axle assembly. Refer to: Axle Assembly (205-02 Rear Drive Axle/Differential, Removal and Installation)...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Automatic Transmission - 10-Speed Automatic Transmission – 10R60

- Engine - 2.3L EcoBoost (201kW/273PS)

- Removal and Installation - Front Halfshaft Speed Sensor

- New on site

- Most important about car

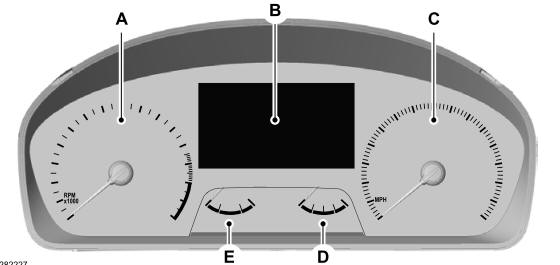

Gauges

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.