Ford Explorer: Engine - 2.3L EcoBoost (201kW/273PS) / Removal and Installation - Intake Manifold

Materials

| Name |

Specification |

Motorcraft® Silicone Brake Caliper Grease and Dielectric Compound

XG-3-A |

ESE-M1C171-A

|

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles. When removing any turbocharger or engine air intake

system component, ensure that no debris enters the system. Failure to

do so may result in damage to the turbocharger.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

Remove the bolts and the suspension support bar.

-

NOTICE:

Do not pull the engine appearance cover forward or

sideways to remove. Failure to press straight upward on the underside of

the cover at the attachment points may result in damage to the cover or

engine components.

-

Remove the engine appearance cover nuts.

-

Place your hand under the engine appearance cover at

the grommet location and push straight up to release the grommet from

the stud.

-

After the grommet has been released from the stud, remove the appearance cover from the engine.

-

Disconnect the battery ground.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables - 2.3L EcoBoost (201kW/273PS))

.

-

Remove the following items:

-

Remove the cowl panel.

Refer to: Cowl Panel (501-02 Front End Body Panels, Removal and Installation).

-

Remove the EVAP canister purge valve.

Refer to: Evaporative Emission Canister Purge Valve (303-13A Evaporative Emissions - 2.3L EcoBoost (201kW/273PS), Removal and Installation).

-

Disconnect the EVAP canister tube quick release coupling and remove from the intake manifold.

Refer to: Quick Release Coupling (310-00 Fuel System - General Information - 2.3L EcoBoost (201kW/273PS))

.

-

Remove the bolt and position the coolant hose and bracket aside.

-

Loosen the CAC tube clamp and position aside.

-

Remove the bolts (Enhanced Hexalobular or TORX PLUS ®

Acument Intellectual Properties, LLC as the owner) and the shield.

-

Detach the retainers, remove the bolt and position the ground wire aside.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

Detach the fuel rail wiring harness retainer from the intake manifold.

-

If equipped, detach the block heater wiring harness retainer from the intake manifold.

-

-

Loosen the clamps and remove the EGR transducer hoses.

-

Remove the bolt and the EGR transducer assembly.

-

Detach the coolant hose retainer from the bottom of intake manifold.

-

Remove the nuts, bolt and position the EGR inlet tube assembly from intake manifold.

-

Remove and discard the EGR inlet tube assembly gasket.

-

-

Disconnect the crankcase vent oil separator tube quick release coupling from the intake manifold.

Refer to: Quick Release Coupling (310-00 Fuel System - General Information - 2.3L EcoBoost (201kW/273PS))

.

-

Remove the bolts and position the intake manifold forward.

-

Detach the KS electrical connector retainers and remove the intake manifold.

-

NOTICE:

If the engine is repaired or replaced because of

upper engine failure, typically including valve or piston damage, check

the intake manifold for metal debris. If metal debris is found, install a

new intake manifold. Failure to follow these instructions can result in

engine damage.

-

Visually inspect the intake manifold for metal debris.

-

-

Visually inspect the intake manifold gaskets for

nicks, cuts and abrasions. If these conditions are not present, the

gaskets may be reused.

-

Clean and inspect all of the sealing surfaces of the intake manifold.

Installation

-

Inspect the turbocharger or engine air intake system components and clean, if necessary.

-

Install the intake manifold and attach the KS electrical connector retainers.

-

-

Position the intake manifold and install the bolts and tighten in sequence shown.

Torque:

18 lb.ft (25 Nm)

-

Connect the crankcase vent oil separator tube quick release coupling to the intake manifold.

Refer to: Quick Release Coupling (310-00 Fuel System - General Information - 2.3L EcoBoost (201kW/273PS))

.

-

Install a new EGR inlet tube assembly gasket.

-

Position the EGR inlet tube assembly to intake manifold and install the nuts and bolt and tighten in sequence shown.

Torque:

97 lb.in (11 Nm)

-

Attach the coolant hose retainer to the bottom of intake manifold.

-

-

Install the EGR transducer assembly and the bolt.

Torque:

97 lb.in (11 Nm)

-

Install the EGR transducer hoses.

-

If equipped, attach the block heater wiring harness retainer to the intake manifold.

-

Attach the fuel rail wiring harness retainer to the intake manifold.

-

-

Connect the wiring harness electrical connectors.

-

Attach the wiring harness retainers.

-

Position the ground wire and install the bolt and attach the retainers.

Torque:

159 lb.in (18 Nm)

-

Install the shield and the bolts (Enhanced Hexalobular

or TORX PLUS ® Acument Intellectual Properties, LLC as the owner).

Torque:

18 lb.ft (25 Nm)

-

Position the CAC tube and tighten the clamp.

Torque:

44 lb.in (5 Nm)

-

Position the coolant hose and bracket and install the bolt.

Torque:

97 lb.in (11 Nm)

-

Install the EVAP canister tube and connect the quick release coupling to the intake manifold.

Refer to: Quick Release Coupling (310-00 Fuel System - General Information - 2.3L EcoBoost (201kW/273PS))

.

-

Install the following items:

-

Install the EVAP canister purge valve.

Refer to: Evaporative Emission Canister Purge Valve (303-13A Evaporative Emissions - 2.3L EcoBoost (201kW/273PS), Removal and Installation).

-

Install the cowl panel.

Refer to: Cowl Panel (501-02 Front End Body Panels, Removal and Installation).

-

Connect the battery ground.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables - 2.3L EcoBoost (201kW/273PS))

.

-

-

NOTE:

Lubricating the grommets with silicone grease

will aid in the installation of the engine appearance cover, and any

future removal and installation of the cover.

Lubricate each grommet with silicone grease.

Material: Motorcraft® Silicone Brake Caliper Grease and Dielectric Compound

/ XG-3-A

(ESE-M1C171-A)

-

Position the engine appearance cover onto engine with the grommet aligned with the stud.

-

Press down on the engine appearance cover at the

grommet location to attach the grommet onto the stud and install the

nuts.

Torque:

44 lb.in (5 Nm)

-

Install the suspension support bar and the bolts.

Torque:

22 lb.ft (30 Nm)

Special Tool(s) /

General Equipment

303-103

(T74P-6375-A)

Holding Tool, FlywheelT74P-77000-ATKIT-2009TC-F

Removal

With the vehicle in NEUTRAL, position it on a hoist...

Special Tool(s) /

General Equipment

Hose Clamp Remover/Installer

Locking Pliers

Removal

NOTE:

During engine repair procedures, cleanliness is extremely

important...

Other information:

Removal

NOTE:

LH (left-hand) side shown, RH (right-hand) side similar.

Remove the rear door latch.

Refer to: Rear Door Latch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

NOTE:

This step is only necessary when installing a new component...

To activate tow mode, use the drive

mode switch on the center console. See Selecting a Drive Mode.

The indicator light illuminates and a message displays in the instrument cluster

when the system becomes active. Select a different mode to turn the system off...

Categories

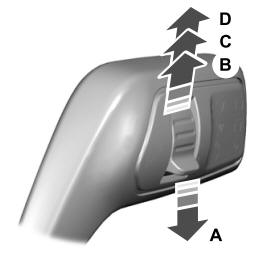

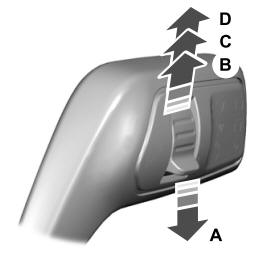

Push the lever up or down to operate

the windshield wipers.

Push the lever up or down to operate

the windshield wipers.

A - Single wipe.

read more

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Removal and Installation - Flexplate

Removal and Installation - Flexplate Removal and Installation - Oil Cooler

Removal and Installation - Oil Cooler Push the lever up or down to operate

the windshield wipers.

Push the lever up or down to operate

the windshield wipers.