Ford Explorer: Body Repairs - General Information / Specifications

General Specifications

| Item | Specification |

|---|---|

| Plug Weld hole | 8 mm (0.315 in) |

| Weld Wire ER70S-3 | 0.9 mm (0.0354 in) - 1.1 mm (0.0433 in) |

| Weld Wire ER70S-6 | 0.9 mm (0.0354 in) - 1.1 mm (0.0433 in) |

Weld Nugget Chart

| Test Thickness of Metal | Nugget Size |

|---|---|

| 0.7 mm (0.0276 in) + 0.7 mm (0.0276 in) | 4.3 mm (0.1693 in) |

| 0.7 mm (0.0276 in) + 0.7 mm (0.0276 in) + 0.7 mm (0.0276 in) | 4.3 mm (0.1693 in) |

| 0.9 mm (0.0354 in) + 0.9 mm (0.0354 in) | 4.7 mm (0.185 in) |

| 0.9 mm (0.0354 in) + 0.9 mm (0.0354 in) + 0.9 mm (0.0354 in) | 4.7 mm (0.185 in) |

| 1 mm (0.0394 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 1 mm (0.0394 in) + 1 mm (0.0394 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 2 mm (0.0787 in) + 2 mm (0.0787 in) | 7.1 mm (0.2795 in) |

| 2 mm (0.0787 in) + 2 mm (0.0787 in) + 2 mm (0.0787 in) | 7.1 mm (0.2795 in) |

| 3 mm (0.1181 in) + 3 mm (0.1181 in) | 8.7 mm (0.3425 in) |

| 3 mm (0.1181 in) + 3 mm (0.1181 in) + 3 mm (0.1181 in) | 8.7 mm (0.3425 in) |

| 3 mm (0.1181 in) + 0.7 mm (0.0276 in) | 4.3 mm (0.1693 in) |

| 0.7 mm (0.0276 in) + 3 mm (0.1181 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 2 mm (0.0787 in) + 2 mm (0.0787 in) + 0.7 mm (0.0276 in) | 4.3 mm (0.1693 in) |

| 0.9 mm (0.0354 in) + 0.9 mm (0.0354 in) + 2 mm (0.0787 in) | 4.7 mm (0.185 in) |

| 2 mm (0.0787 in) + 0.9 mm (0.0354 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 1 mm (0.0394 in) + 3 mm (0.1181 in) + 1 mm (0.0394 in) | 5.2 mm (0.2047 in) |

| 3 mm (0.1181 in) + 1 mm (0.0394 in) + 2 mm (0.0787 in) | 7.1 mm (0.2795 in) |

| 0.9 mm (0.0354 in) + 0.7 mm (0.0276 in) + 0.9 mm (0.0354 in) | 4.3 mm (0.1693 in) |

Ford Recommended Steel Repairability Matrix

| Grade | Trade Descriptions | Welding Method | Cold Repairs | Use of Heat for Repair | Temperature Range | Maximum Heat | ||

|---|---|---|---|---|---|---|---|---|

| MIG | Squeeze-Type Resistance Spot Welding (STRW) | MIG Braze | ||||||

| Mild Steel | Mild | Yes | Yes | N/A | Yesa | Yes | Up to 650° C (1,200° F) | 90 seconds x 2 |

| Laminate Steel | Quiet Steel | No | Yes | No | Yesa | NA | NA | NA |

| Bake Hardened Steel (BH) | Bake Hardened Steel (BH) 180, 200, 210, 220, 250, 280 | Yes | Yes | Yesb | Yesa | Yes | Up to 650° C (1,200° F) | 90 seconds x 2 |

| Solid Solution Strengthened | - | Yes | Yes | Yesb | Yesa | Yes | Up to 650° C (1,200° F) | 90 seconds x 2 |

| High-Strength Low Alloy (HSLA) | High-Strength Low Alloy (HSLA) 200, High-Strength Low Alloy (HSLA 250, High-Strength Low Alloy (HSLA 260, High-Strength Low Alloy (HSLA 300, High-Strength Low Alloy (HSLA 340, High-Strength Low Alloy (HSLA 350, High-Strength Low Alloy (HSLA 500, High-Strength Low Alloy (HSLA) 550 | Yes | Yes | Yesb | Yesa | Yes | Up to 650° C (1,200° F) | 90 seconds x 2 |

| Dual Phase Steel (DP) | Dual Phase Steel (DP) 500, Dual Phase Steel (DP) 600 | Yes | Yes | Yesb | Yesa | No | NA | NA |

| Dual Phase Steel (DP)c | Dual Phase Steel (DP) 700, Dual Phase Steel (DP) 900 and Dual Phase Steel (DP) 1,000 | Yesd | Yes | Yesb | No | No | NA | NA |

| Ultra High Strength Steel (UHSS) (Martensitic, Boron)e | Boron, Martensitic | Yesa | Yes | Yesb | No | No | NA | NA |

| Transformation Induced Plasticity Steel (TRIP) | Transformation Induced Plasticity Steel (TRIP) 590, Transformation Induced Plasticity Steel (TRIP) 780, Transformation Induced Plasticity Steel (TRIP) 980 | NA | NA | NA | NA | NA | NA | NA |

aCold repairs can be performed if damage excludes kinks. May section only if approved procedure in workshop manual.

bMetal Inert Gas (MIG) braze allowed for non-structural applications only.

cDual phase steels DP 700 class, DP 900 class and DP 1,000 class must be replaced at factory joints, no sectioning unless approved procedure in workshop manual.

dFor DP 900, 1,000 and Boron use Metal Inert Gas (MIG) plug welding only, no stitch welding.

eBoron and Ultra High Strength Steel (UHSS)-Mortensite components must be replaced at factory joints, no sectioning allowed.

Description and Operation - Complete Panel Replacement/Partial Replacement

Description and Operation - Complete Panel Replacement/Partial Replacement

Partial Replacement

Item

Description

1

Sectioning area

2

Manufacture weld joint

Decision Criteria

The following ..

Other information:

Ford Explorer 2020-2024 Service Manual: Removal and Installation - Engine Coolant Temperature (ECT) Sensor

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the EGR cooler. Refer to: Exhaust Gas Recirculation (EGR) Cooler (303-08A Engine Emission Control - 2.3L EcoBoost (201kW/273PS), Removal and Installation)...

Ford Explorer 2020-2024 Owners Manual: Refueling - Hybrid Electric Vehicle (HEV)

WARNING: Do not overfill the fuel tank. The pressure in an overfilled tank may cause leakage and lead to fuel spray and fire. WARNING: Do not pry open the fuel tank filler valve. This could damage the fuel system. Failure to follow this instruction could result in fire, personal injury or death...

Categories

- Manuals Home

- 6th Generation Explorer Owners Manual

- 6th Generation Explorer Service Manual

- Interior Trim and Ornamentation

- General Procedures - Transmission Fluid Drain and Refill

- Body and Paint

- New on site

- Most important about car

Gauges

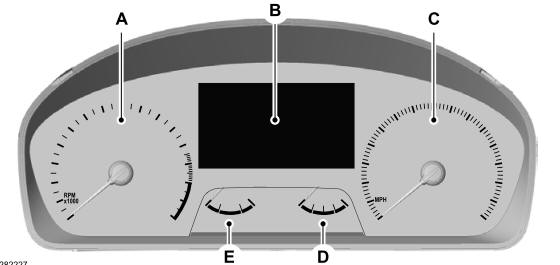

4 Inch Display

A - Tachometer.

B - Information display.

C - Speedometer.

D - Fuel gauge.

E - Engine coolant temperature gauge.